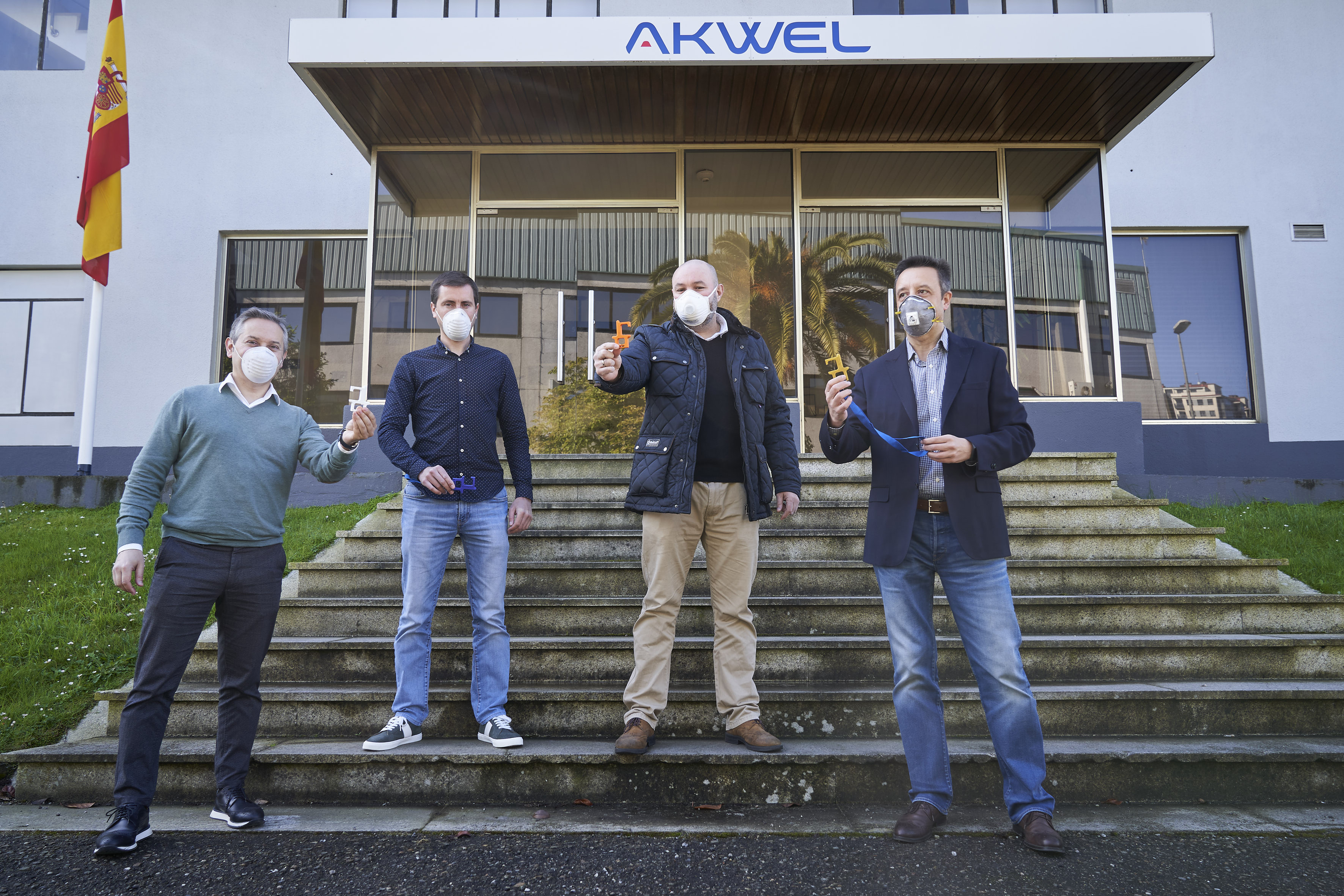

The Galician Metalworkers Industrial Association (Asime) and the University of Vigo launched a new solidarity initiative in collaboration with four Galician companies: Lupeon, Dativic, Roviño5 and Akwel Automotive. Based on the work done by Lupeon and Dativic, this group of companies and organizations will take the production of this device to the next level, through modeling and plastic injection.

The so-called LU-Touch is a tool for opening and closing doors and windows, which can also act as a push-button for buttons and switches, so that direct contact with surfaces is avoided and the risks of contagion are limited.

The system was devised a few weeks ago by Lupeon, in collaboration with its subsidiary logistics company Dativic. Given the significant demand received, the company joined forces with the other two companies involved, under the coordination of Asime and the University of Vigo, in order to increase its productive capacity.

A company of recognized prestige in the mold sector, and Akwel Automotive, manufacturer of equipment and systems for the automotive and heavy vehicle industry.

Roviño5 carried out the design and manufacture of a mold with two cavities for the manufacture of Lu_ Touch by means of plastic injection, while the injection process was carried out at the Akwel plant in Vigo.

While Lupeon had the capacity to produce a maximum of 400 pieces per day through 3D printing, the union of forces made it possible to produce 10,000 pieces in record time, which were distributed throughout Spain.

The device is specially designed for healthcare personnel, state security forces and bodies, and social services, but also for companies or workers in any sector who may need it. It has an ergonomic design that makes it easy to operate with just three fingers. The grip area is completely separated from the contact area and offers the possibility of being carried by hanging it from the neck or from the waist. It can be easily disinfected, using 70% alcohol solutions, or alternatively with bleach or soap.